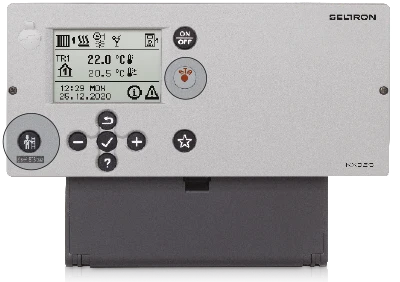

Weather compensated and boiler controller KXD10B

Presentation

KXD10B are powerful boiler and weather compensated controllers, which also provide the control of room heating and domestic hot water heating in addition to the liquid fuel boiler control.

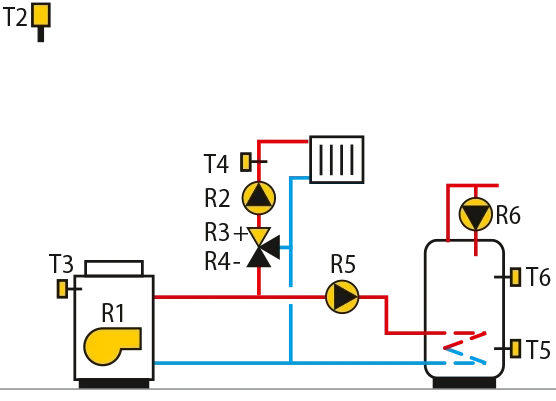

- Liquid fuel boiler control.

- Radiator room heating system control.

- Floor heating or cooling system control.

- Convector heating or cooling system control.

- Wall or ceiling heating or cooling system control.

- Domestic hot water heating.

Features

- 7 preset hydraulic schemes.

- Boiler and room control.

- Safety functions for boiler protection (Frost and overheating protection of boiler, mechanical thermo fuse to switch the boiler off at exceeded temperature 110 °C).

- Room heating or cooling according to the time programme.

- Domestic hot water heating according to the time programme.

- Control of heating systems with a storage tank.

- The possibility of connecting 2 room units.

- BOOST function for intense room heating.

- Integrated solar system protection features.

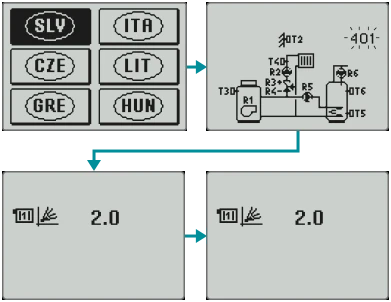

- 13-language user interface.

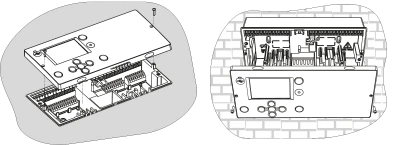

- It can be installed on the wall, in the boiler housing or to the external boiler panels by means of a console.

- Wizard for an easy and quick device start-up.

- Operational diagnostics featuring error and excessive temperature warnings.

- Remote control with the help of the SeltronHome system.

Documentation

Download

Outlined functions

Start-up wizard

Step 1: language selection.

Step 2: hydraulic scheme selection.

Step 3: setting the heating curve for the first heating circuit.

Step 4: setting the heating curve for the second heating circuit.

KXD Emission measurement and STB testing

By pressing the STB key, we activate the thermal fuse test. In this mode, the controller starts the boiler and heats it to 110 °C or until the STB fuse switches it off.

The red-coloured STB symbol informs that the thermal fuse is active.

KXD controller installation

KXD Remote control with the help of SeltronHome system

Typical hydraulic connection

Technical data

| Tehnični podatki | KXD10B |

|---|---|

| Backlit graphic display |  |

| Operating hours meter |  |

| Weekly program timer |  |

| Integrated STB thermal protection |  |

| Connection voltage | 230 V~, 50 Hz |

| Own consumption | 4.5 W |

| Standby power consumption | Max. 0.5 W |

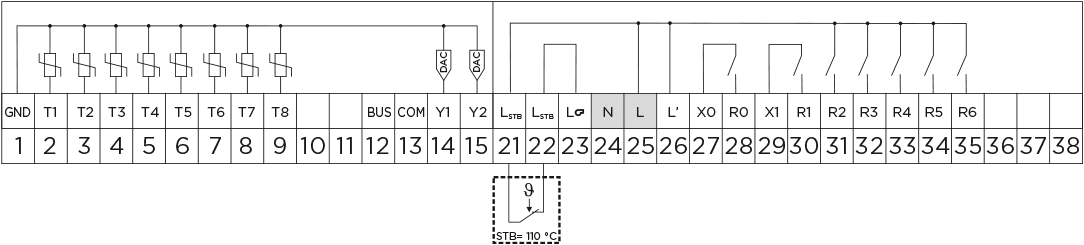

| No. of inputs | 8 pcs temperature sensor (Pt 1000) |

| No. of outputs | 7 pcs mechanical 2 pcs PWM or analogue 0÷10 V (Y2) |

| Relay outputs | 4 (1) A ~, 230 V~ |

| Triac outputs | 1 (1) A ~, 230 V~ |

| Power supply of built-in clock | Battery CR2032 (Li-Mn) 3 V |

| Accuracy of built-in clock | +/-1 s (24 h) at 20 °C |

| Degree of protection | IP20 according to EN 60529 |

| Safety class | II according to EN 60730-1 |

| Operation mode | 1B according to EN 60730-1 |

| Type of temperature sensors | Pt1000 or KTY10 |

| Operation mode | 3-point PID |

| Housing material | ASA + PC – thermoplastic |

| Permissible ambient temperature | 5÷40 °C |

| Storage temperature | -20÷65 °C |

| Product weight | 1.070 g |

| Number of pieces in a package unit | 6 pieces |

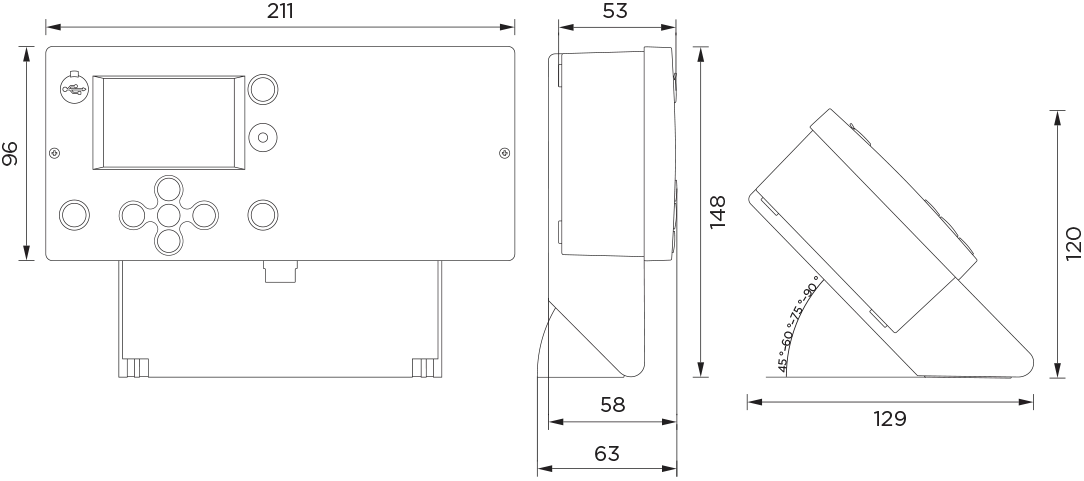

| Dimensions |  |

| Electrical connection |  |

Performance comparison

| KXD10B | KXD10 | KXD20 | |

|---|---|---|---|

| Application | |||

| Reguliranje kotlov na tekoče kurivo |  |  |  |

| Radiator room heating system control |  |  |  |

| Floor heating or cooling system control |  |  |  |

| Convector heating or cooling system control |  |  |  |

| Wall or ceiling heating or cooling system control |  |  |  |

| Domestic hot water heating |  |  |  |

| Technical characteristics | |||

| No. of preset hydraulic schemes | 7 | 17 | 52 |

| No. of room units | 2 | 2 | 2 |

| No. of mechanical relays | 7 | 8 | 9 |

| Number of electronic relays | — | 1 | 1 |

| No. of temperature sensor inputs | 8 | 8 | 8 |

| No. of analogue outputs (0÷10 V or PWM) for the control of the circulation pump or an energy source | 2 | 2 | 2 |

| Možnost BUS-povezave regulatorjev KXD med seboj in z drugimi regulatorji Seltron |  |  |  |

| System control | |||

| Ogrevalnega sistema z radiatorji |  |  |  |

| Sistema talnega ogrevanja |  |  |  |

| Konvektorskega sistema ogrevanja |  |  |  |

| Sistema stenskega in stropnega ogrevanja |  |  |  |

| Sistema ogrevanja sanitarne vode |  |  |  |

| Heating circuits control | |||

| Direktnega ogrevalnega kroga |  |  |  |

| Mešalnega ogrevalnega kroga |  |  |  |

| Direktnega in mešalnega ogrevalnega kroga | — |  |  |

| Dveh mešalnih ogrevalnih krogov | — | — |  |

| Domestic hot water heating |  |  |  |

| Switchover between direct heating circuit and domestic hot water heating |  |  |  |

| Domestic hot water circulation |  |  |  |

| Automatic switchover between heat sources | — | — |  |

| Control of the supply line constant temperature |  |  |  |

| Single-stage storage tank loading | — | — |  |

| Heat source control | |||

| Solid fuel boiler |  |  |  |

| Solid fuel boiler with a pellet burner | — | — |  |

| Liquid fuel boiler |  |  |  |

| Liquid fuel boiler with a two-stage burner |  |  |  |

| Combined boiler | — | — |  |

| Gas flow boiler | — | — |  |

| Heat pump | — | — |  |

| Storage tank |  |  |  |

| Auxiliary heating with electricity |  |  |  |

| Solar collectors | — |  |  |

| Domestic hot water heating | |||

| With a primary heating source |  |  |  |

| With a storage tank |  |  |  |

| Using a solar system | — |  |  |

| User functions | |||

| Room heating or cooling according to the time programme |  |  |  |

| Automatic winter/summer mode switchover |  |  |  |

| PARTY function – activation of the comfort operation mode |  |  |  |

| ECO function – activation of the economy operation mode |  |  |  |

| HOLIDAY function – activation of the operation mode during the holiday season |  |  |  |

| Domestic hot water heating according to the time programme |  |  |  |

| One-time domestic hot water heating |  |  |  |

| BOOST function for intense room heating |  |  |  |

| Function for screed drying |  |  |  |

| Heating system protection | |||

| Anti-legionella protection (for a controlled energy source) |  |  |  |

| Storage tank overheating protection |  |  |  |

| Boiler overheating protection |  |  |  |

| Collector frost protection | — |  |  |

| Forced pump start at the highest collector temperature | — |  |  |

| Switching off of the pump when the safety temperature has been exceeded | — |  |  |

| Solar system protection when collectors are overheating | — |  |  |

| Storage tank recooling to the desired temperature | — |  |  |

| Periodic start of the pump and mixing valve during a period of inactivity |  |  |  |

| A comprehensive overview of the heating system operation | |||

| Graphic display of temperatures according to days of the last week |  |  |  |

| Detailed display of temperatures for the current day |  |  |  |

| Notifications on the activated protection functions and warnings about system failures |  |  |  |

| Possibility to simulate sensors and analyse the system operation. |  |  |  |

| Remote access | |||

| Possibility of USB connection to a PC |  |  |  |

| Possibility of connectivity to the SeltronHome platform, which allows remote control via a smartphone or tablet |  |  |  |

| Setup and installation | |||

| Wizard for an easy and quick device start-up |  |  |  |

| 13-language user interface |  |  |  |

| Jeziki: ENG, DEU FRE, DUT, POL, SPA, SLV, ITA, CZE, LIT, GRE, HUN, HRV |  |  |  |

| Setting up the operation by selecting the hydraulic scheme |  |  |  |

| “Help” button for quick help with the setup |  |  |  |

| Graphically adjustable time programmes |  |  |  |

| Option to simulate the system operation |  |  |  |

| Logging and display of changes made to the setup |  |  |  |

| Option for retrieval of the basic setup in the event of data loss or unwanted changes |  |  |  |

| Option for programming free outputs |  |  |  |

| Možnost montaže na steno, v ohišje kotla ali s pomočjo konzole na plašč kotla |  |  |  |

| Simple installation and connection |  |  |  |

Complementary products

-

Room unit RCD20

Digital room unit RCD20 is intended to control room temperature...

-

Communication interface GWD

The GWD3E communication interface is intended for connection of Seltron controllers, room units...

-

Actuators AVD

AVD actuators are intended for position control of rotary mixing and ball valves.

-

Immersion temperature sensor TF/Pt

Potopno temperaturno tipalo TF/Pt se uporablja za merjenje temperature v…

-

Surface temperature sensor VF/Pt

Naležno temperaturno tipalo VF/Pt se uporablja za merjenje temperature v…

-

Outdoor temperature sensor AFD

AFD sensor is used for measurement of outdoor temperature in Seltron controllers.

-

Flue gas temperature sensor CF/Pt

The CF/Pt temperature sensor belongs to the optional equipment range for Seltron heating controllers.