Constant temperature controller SCC40

0%

Presentation

The constant temperature controller SCC40 provides a constant inflow or return temperature with the option of a single- and two-stage storage tank loading.

- Regulation of return temperature of the solid fuel boilers.

- Single-stage storage tank loading.

- Two-stage storage tank loading.

Features

- 6 preset hydraulic schemes.

- Option for controlling mixing valves according to the temperature of the pipelines and the source.

- The option for controlling the pump according to the temperature of the pipeline and the source.

- Possibility to simulate sensors and analyse the system operation.

- 4 mechanical relays.

- 2 solid state relays.

- 7 temperature sensor inputs.

- 3 output for free programming.

- 3 freely programmable outputs.

Documentation

Download

Outlined functions

Start-up wizard

Measurement of the energy obtained

When the solar system is also used for domestic hot water heating, we want to know how much heating energy has been obtained from the solar system.

The SCC controllers allow for an informative and accurate measurement of the solar energy obtained and the display of the data in weekly, monthly and yearly diagrams.

The SCC controllers allow for an informative and accurate measurement of the solar energy obtained and the display of the data in weekly, monthly and yearly diagrams.

- For informative measurements of the solar energy obtained, the maximum reading of the medium flow from the mechanical meter must be entered in the controller setup.

- For accurate measurements of the solar energy obtained, a flow meter with a pulse generator or a Vortex flow meter (VFS) must be installed in the solar system.

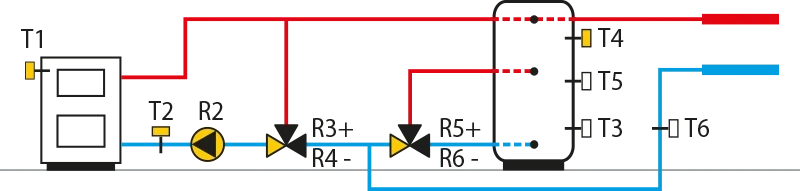

Typical hydraulic connection

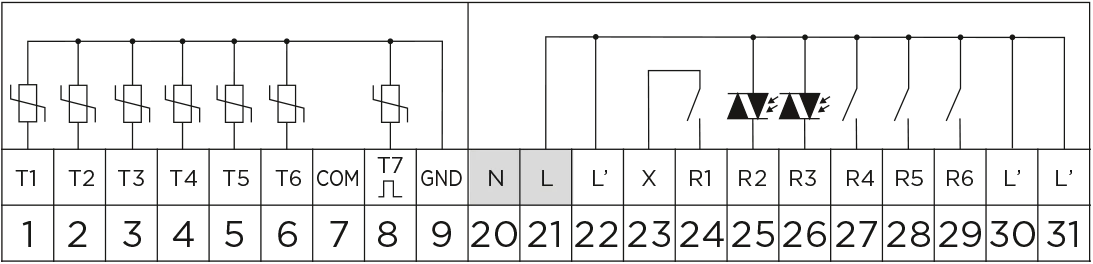

Technical data

| Tehnični podatki | SCC40 |

|---|---|

| Backlit graphic display |  |

| Operating hours meter |  |

| Program timer |  |

| Connection voltage | 230 V~, 50 Hz |

| Own consumption | 2.5 W |

| Standby power consumption | Max. 0.5 W |

| No. of outputs | 7 pcs temperature sensor (Pt 1000) 1 pc pulse input |

| No. of outputs | 2 x triac (R2, R3) 4 x rele (R1, R4, R5, 56) |

| Relay outputs | 4 (1) A ~, 230 V~ |

| Triac outputs | 1 (1) A ~, 230 V~ |

| Power supply of built-in clock | Battery CR2032 (Li-Mn) 3 V |

| Accuracy of built-in clock | +/-1 s (24 h) at 20 °C |

| Degree of protection | I po P20 / EN60529 |

| Safety class | I according to EN 60730-1 |

| Operation mode | 1B according to EN 60730-1 |

| Type of temperature sensors | Pt1000 or KTY10 |

| Housing material | ASA – thermoplastic |

| Operating temperature | 5÷40 °C |

| Storage temperature | -20÷65 °C |

| Product weight | 410 g |

| Number of pieces in a package unit | 6 pieces |

| Dimensions |  |

| Electrical connection |  |

Performance comparison

| SCC30 | SCC40 | |

|---|---|---|

| Application | ||

| Solid fuel boiler return temperature control |  |  |

| Storage tank loading |  |  |

| Control of a pellet or combined boiler |  |  |

| Technical characteristics | ||

| No. of preset hydraulic schemes | 2 | 6 |

| No. of storage tanks | 1 | 2 |

| No. of mechanical relays | 2 | 4 |

| Number of electronic relays | 2 | 2 |

| No. of temperature sensor inputs | 7 | 7 |

| Additional sensor for measuring the source temperature |  |  |

| Option for controlling mixing valves according to the temperature of the pipelines and the source |  |  |

| The option for controlling the pump according to the temperature of the pipeline and the source |  |  |

| Measurement of the energy obtained (kWh) |  |  |

| Option for pulse meter flow measurement (l/min) |  |  |

| Free programming option | 1 output | up to 3 outputs |

| System control | ||

| Single-stage storage tank loading |  |  |

| Two-stage storage tank loading | — |  |

| Heat source control | ||

| Pellet boiler |  |  |

| Heating system protection | ||

| Boiler overheating protection |  |  |

| Antiblock function for pumps |  |  |

| Antiblock function for pumps and diverting valves | — |  |

| A comprehensive overview of the heating system operation | ||

| Graphic display of temperatures according to days of the last week |  |  |

| Detailed display of temperatures for the current day |  |  |

| Notifications on the activated protection functions and warnings about system failures |  |  |

| Possibility to simulate sensors and analyse the system operation. |  |  |

| Remote access | ||

| Possibility of USB connection to a PC |  |  |

| Setup and installation | ||

| Wizard for an easy and quick device start-up |  |  |

| 13-language user interface |  |  |

| Languages: EN, DE, FR, NL, PL, ES, SL, IT, CS, LT, GR, HU, HR |  |  |

| Setting up the operation by selecting the hydraulic scheme |  |  |

| “Help” button for quick help with the setup |  |  |

| Graphically adjustable time programmes |  |  |

| Option to simulate the system operation |  |  |

| Logging and display of changes made to the setup |  |  |

| Option for retrieval of the basic setup in the event of data loss or unwanted changes |  |  |

| Option for programming free outputs |  |  |

| Possibility of wall or DIN rail installation |  |  |

| Simple installation and connection |  |  |

Complementary products

-

Actuators AVD

AVD actuators are intended for position control of rotary mixing and ball valves.

-

Immersion temperature sensor TF/Pt

Potopno temperaturno tipalo TF/Pt se uporablja za merjenje temperature v…

-

Surface temperature sensor VF/Pt

Naležno temperaturno tipalo VF/Pt se uporablja za merjenje temperature v…